Here’s the uncomfortable truth about scaling woodworking operations: the techniques that work beautifully for custom, one-off projects become productivity killers when you need to produce hundreds of identical components.

That reliable benchtop pocket hole jig that served you well for years suddenly becomes the constraint limiting your entire production line. When you’re drilling pocket holes for 50 face frames a day instead of 5, every manual adjustment, every positioning step, every second of setup time multiplies into hours of lost productivity.

I’ve watched countless shops hit this wall. They try to solve capacity problems by adding more workers or running longer hours, only to discover that their equipment, not their labor, is the limiting factor.

The Hidden Costs of Manual Operations

Consider what happens with traditional pocket hole jigs at production volumes:

- Manual positioning and measuring for every single hole

- Operator fatigue leading to inconsistent results by afternoon

- Setup time between different material thicknesses

- Quality variations as workers rush to meet deadlines

A face frame that takes 8 minutes on a benchtop jig drops to 90 seconds on a proper production machine. Multiply that across hundreds of frames, and you’re talking about transformational time savings.

The Engineering That Makes Production Possible

Pneumatic vs. Manual Operation: The Speed Revolution

Production machines eliminate the human inconsistency factor by automating the drilling process. Pneumatic systems deliver consistent downward pressure and drilling speed regardless of material density or how tired your operator gets at the end of a long day.

Castle TSM-35 machines exemplify this approach, with 1.5 to 2-second cycle times that would be impossible to achieve manually. The pneumatic system doesn’t get tired, doesn’t vary pressure based on mood, and doesn’t slow down as the day progresses.

Precision Positioning Systems: Eliminating Human Error

The difference between production and benchtop machines isn’t just speed—it’s consistency. Production machines incorporate adjustable fences, mechanical stops, and quick-change fixtures that eliminate manual measurement and positioning.

Here’s why this matters: measuring and positioning workpieces manually introduces variation with every single piece. Over hundreds of components, these small variations compound into assembly problems, quality issues, and frustrated workers trying to make pieces fit that should be identical.

Heat Management for Continuous Operation

When machines run continuously for hours, thermal expansion becomes a precision killer. Production machines feature enhanced cooling systems and robust construction designed to dissipate heat effectively, maintaining accuracy even during marathon production runs.

I’ve seen shops try to solve capacity problems by running benchtop machines continuously, only to discover that precision drifts after a few hours of continuous operation. Production machines solve this problem through engineering, not operator management.

Matching Machine Capability to Production Requirements

Mid-Range Production: The Sweet Spot for Growing Shops

For many operations, machines in the $4,500 to $6,000 range provide the essential production features without industrial complexity. The Kreg DK1100 series exemplifies this category, offering multiple configurations that optimize for different applications.

The FP model at $4,999 might optimize for face frame production with specialized fixtures, while the TP variant at $4,499 could feature different capabilities for varied joint applications. This flexibility lets you optimize for your specific product mix without investing in multiple dedicated machines.

Real-World ROI Analysis

A furniture manufacturer in North Carolina calculated their return on a $5,000 production machine:

- Previous manual process: 15 minutes per face frame

- New automated process: 2 minutes per face frame

- Labor savings: 13 minutes × $25/hour = $5.42 per frame

- Monthly volume: 400 frames

- Monthly savings: $2,168

- Payback period: 2.3 months

This doesn’t even account for improved quality consistency, reduced worker fatigue, or the ability to take on larger contracts with confidence.

Heavy-Duty Production: Maximum Throughput

When your operation demands unwavering reliability and maximum throughput, machines in the $7,000 to $9,000 range provide the robust construction necessary for truly high-volume production. The Ritter R200T at $7,390 represents this category’s approach to serious production requirements.

These machines typically feature enhanced automation capabilities that go beyond basic pneumatic operation. Programmable positioning systems can store multiple setup configurations, allowing quick changeovers between different product types without lengthy manual adjustments.

A millwork company in Oregon upgraded to heavy-duty production equipment and immediately saw:

- 40% increase in daily output

- 60% reduction in setup time between jobs

- 75% reduction in quality-related rework

- Ability to bid on contracts they previously couldn’t handle

Industrial-Grade Solutions: Complete Production Systems

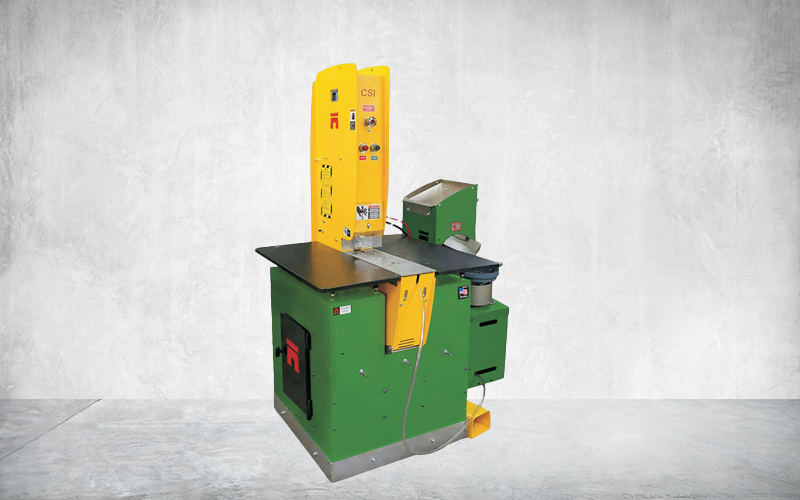

At the pinnacle of capability, industrial systems like the CSI-1.5D at $59,999 represent complete production cells rather than individual machines.

These systems integrate pocket hole drilling with material handling, positioning, and often screw insertion into automated production processes capable of operating with minimal human intervention.

When Industrial Makes Sense

Industrial systems justify their investment through:

- Continuous operation with minimal labor input

- Exceptional quality consistency across thousands of components

- Integration with upstream and downstream production equipment

- CNC control systems that store hundreds of different part programs

A large furniture manufacturer implemented an industrial pocket hole system and achieved:

- 200% increase in production capacity

- 90% reduction in labor costs per component

- Ability to operate lights-out production shifts

- Quality consistency that eliminated downstream assembly problems

Optimizing Your Production Workflow

Analyzing Your Current Bottlenecks

Before selecting production equipment, honestly assess where time gets spent in your current process:

- How much time per piece on setup and positioning?

- How many different product configurations do you run?

- Where do quality problems typically occur?

- What’s your current capacity utilization?

Understanding these factors helps determine which features provide the greatest value for your specific operation.

Material Handling Integration

In high-volume applications, the time required to position, clamp, and remove workpieces significantly impacts overall throughput. Features like pneumatic clamping, automatic part ejection, or integration with material handling systems become valuable productivity enhancements.

One cabinet shop discovered that material handling took 30% of their total cycle time. Investing in automated clamping and part ejection reduced their cycle time by 25% and eliminated operator fatigue issues.

Quality Control at Scale

Production volume amplifies both efficiency gains and quality problems. Operations requiring exceptional consistency might justify additional investment in machines with advanced positioning systems and automated controls.

Consider:

- Tolerance requirements for your end products

- Cost of quality problems vs. prevention

- Customer expectations for consistency

- Rework and warranty costs

Making the Investment Decision

Beyond Initial Cost: Total Cost of Ownership

When evaluating production equipment, consider:

- Labor savings per component

- Quality improvement value

- Capacity expansion capability

- Maintenance and operating costs

- Energy efficiency

A construction company building residential developments calculated that their $8,000 production machine saved $847 per week in labor costs alone, paying for itself in less than 10 weeks.

Financing Production Equipment

Most manufacturers offer financing options that let you match equipment payments to the cash flow improvements they generate. This approach turns equipment investments into cash flow positive decisions rather than capital expenditures.

Infrastructure Requirements

Production machines often require:

- Three-phase electrical power

- Compressed air systems

- Enhanced dust collection

- Adequate floor space and mounting

- Operator training

Factor these requirements into your total investment planning.

Workflow Integration Strategies

Upstream and Downstream Coordination

Production pocket hole machines work best when integrated into optimized workflows. Consider how pocket hole drilling fits with:

- Material preparation and sizing

- Other machining operations

- Assembly processes

- Finishing requirements

Changeover Optimization

For operations producing multiple product types, changeover time between different setups can significantly impact productivity. Look for machines with:

- Quick-change fixtures

- Programmable positioning systems

- Minimal manual adjustments

- Clear setup documentation

Operator Training and Safety

Production equipment requires proper training for both productivity and safety. Plan for:

- Initial operator certification

- Ongoing safety training

- Maintenance training

- Productivity optimization

Common Implementation Challenges

Underestimating Infrastructure Needs

Many shops focus on the machine cost while underestimating infrastructure requirements. Plan for electrical, pneumatic, and workspace modifications early in your decision process.

Inadequate Dust Collection

Production speeds generate significantly more dust and chips than benchtop operations. Inadequate dust collection affects both air quality and machine performance.

Insufficient Training

Production equipment capabilities require proper training to realize their full potential. Rushing into production without adequate operator training wastes the investment.

Measuring Success

Key Performance Indicators

Track metrics that matter:

- Components per hour/shift/day

- Setup time between different products

- Quality consistency (rework rates)

- Labor hours per component

- Overall equipment effectiveness

Continuous Improvement

Production equipment enables continuous improvement through:

- Process optimization

- Workflow refinement

- Quality system development

- Capacity planning

The Scaling Decision

Choosing production pocket hole equipment isn’t just about buying a bigger machine—it’s about systematically removing constraints that limit your growth potential.

The shops that successfully scale understand that equipment investments should enable capability expansion, not just efficiency improvements. The right production machine lets you bid on contracts you couldn’t handle before, deliver quality you couldn’t achieve consistently, and operate at volumes that transform your business model.

Explore Wurth Baer’s complete production equipment lineup to find the solution that matches your scaling requirements and growth objectives.

Remember Dave from Chicago? His success wasn’t just about buying a machine—it was about matching production capability to market opportunity. When the next big contract comes along, you want to be ready to say yes with confidence.

The question isn’t whether production equipment costs more than benchtop machines. The question is whether the constraint limiting your growth is equipment capacity or market opportunity. For most successful operations, equipment becomes the easier problem to solve

No responses yet